TwoShot Injection MoldingPlastic Technologies Handbook

Shot Weight Calculation Injection Moulding Pdf Blog Dandk

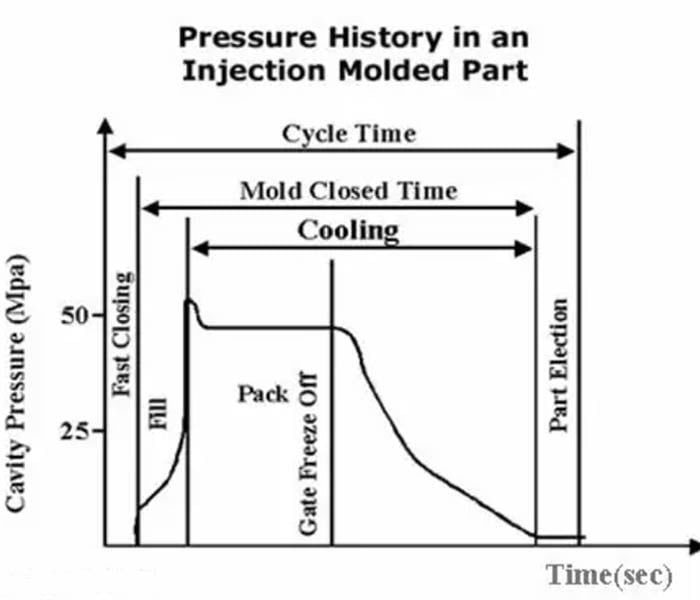

availability, shot sizes as low as 30 to 35% may be used with the understanding that the processing latitude of the material may be significantly reduced. Lower stock temperatures mean higher melt viscosity and more resistance to flow. Greater injection pressures will be needed to fill the part and molded-in stresses may result.

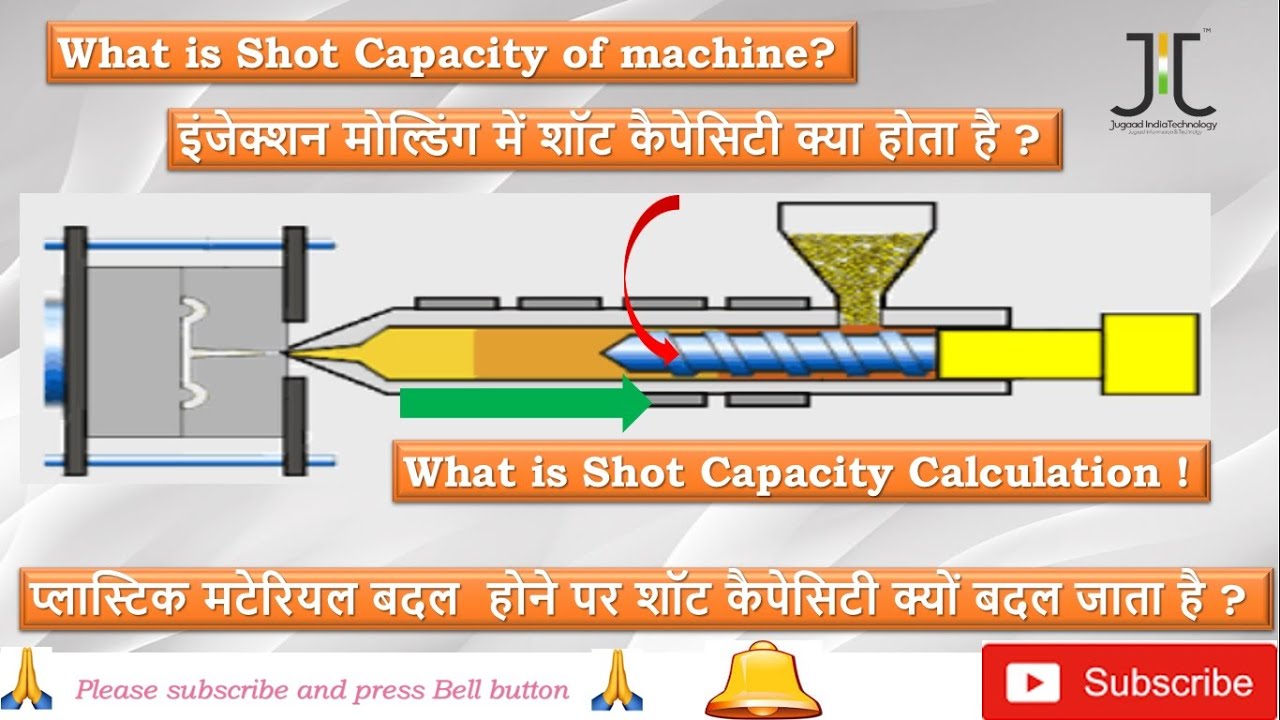

Shot size calculation in injection molding machine YouTube

The shot size is the maximum amount of plastic injection mold that can be injected in one molding cycle. Pellets are fed through the hopper into the barrel and screw assembly. The barrel supports the reciprocating screw where the material is then melted through conduction from the electric resistance heater bands surrounding the barrel.

How to calculate Injection molding machine shot weight capacity I shot capacity calculation

The formula the calculator uses is: Shot Size = Part Volume x (1 + Shrinkage / 100) x Safety Factor. Where: Part Volume: The volume of the part to be molded (in cubic units) Shrinkage: The shrinkage rate of the material (expressed as a percentage) Safety Factor: A multiplier (usually between 1.5 and 2) to compensate for process variables.

Injection MoldingInjection Moulding Service

The formula is as follows: Shot size = (mould volume) x (material density) x (desired part weight) For example, if your mould has a volume of 1000cc, the material being used has a density of 1.2g/cc, and the desired part weight is 50 grams, the shot size would be: Shot size = 1000cc x 1.2g/cc x 50g = 60,000 cubic millimeters (mm3) In conclusion.

INJECTION MOULDING (SHOT SIZE SETTING) YouTube

In the third part of our series, we'll be going over how to appropriately size the injection unit on a molding machine. Continue watching the rest of the vid.

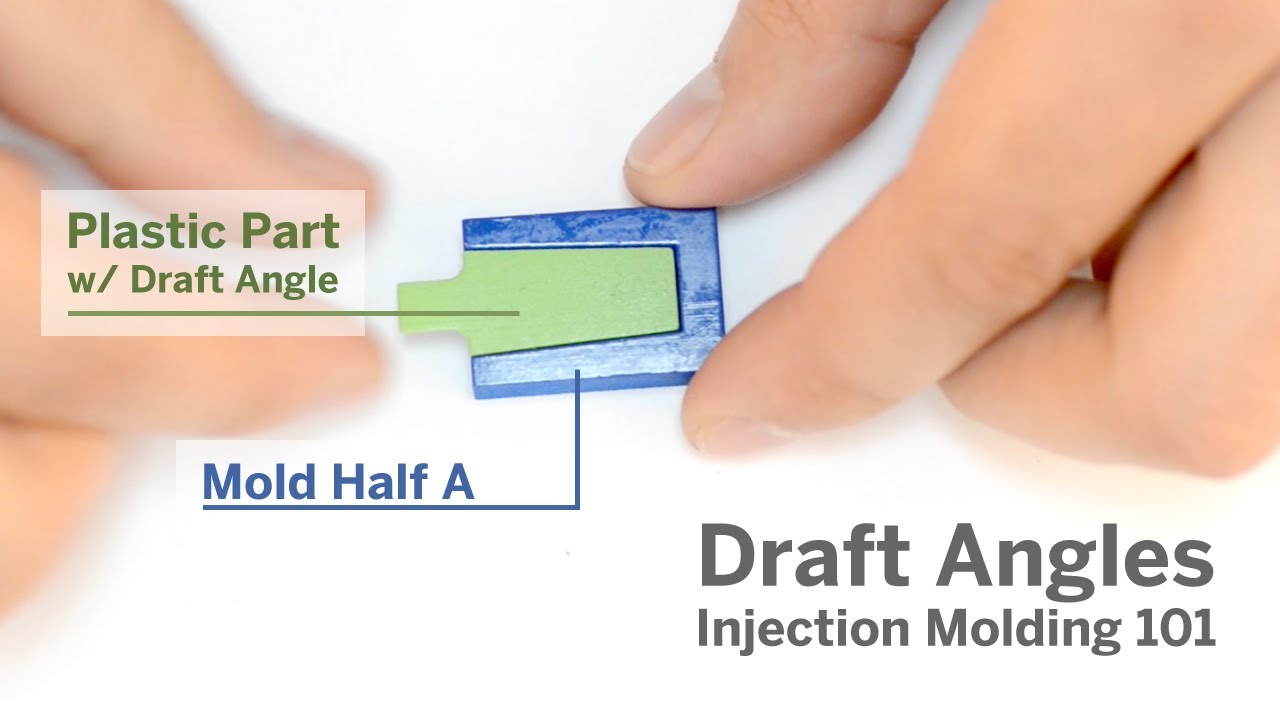

Injection Molding 101 Draft Angles YouTube

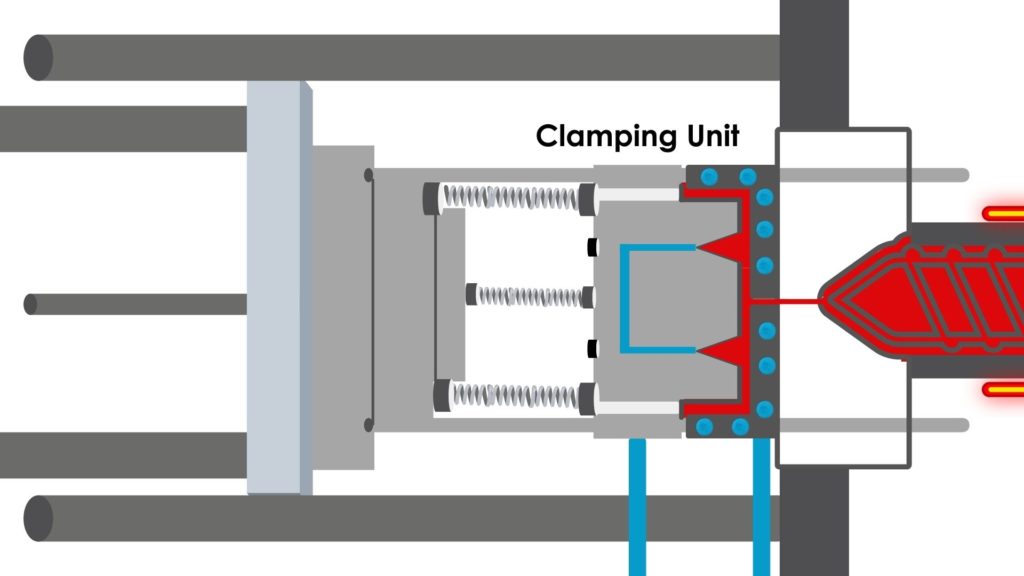

Part 1. Clamping tonnage F (TON) Formula: F=Am*Pv/1000. Clamping tonnage: TON Am: Mold Cavity Projected area: CM2. Filling Pressure: KG/CM2. Generally, the plastic material filling pressure range is 150-350KG/CM2) Good flowability takes bottom values, poor flowability takes top values. Injection Pressure= filling pressure/0.4-0.6.

Injection Molding 101 Undercuts YouTube

The process has to factor in screw slippage, room for the non-return valve to seat, and some decompression after screw rotate. These factors are hard to predict or calculate, so if you go over 75% shot size you can expect trouble. Also, large shots require longer screw rotate times that eat into profit margins.

Injection Molding Shot Size Calculation Online CalculatorsHub

This formula is used to calculate the force required to clamp the mold halves during injection molding. Generally, the cavity pressure inside the mold is within the range of approximately 300 to 500 kgf/cm 2. The total projection area is the total of the projected areas of the cavities and runners in relation to the parting surface.

Injection Molding Calculation Building Engineering Materials

To calculate the capacity of an injection moulding machine, use the formula mass divided by density, for instance, if the machine screw diameter is 28mm, the material density is 1.52g/cm3 (for PVC material), with a screw weight of 40.6g, the shot size or machine shot capacity would be 43.4mm. What is the tonnage capacity of injection molding.

Two Shot & Multi Shot Injection Molding Gemini Group

For PS the melt density is 0.945 g/cm 3 and for PP it is about 0.74 g/cm 3. This changes the ratio for our calculation; it is now 0.945/0.74 or 1.28. Now we need a minimum of 6.16 x 1.28 or 7.88 oz of shot capacity. We are still (just barely) within our 8-oz barrel capacity, but unfortunately Mr. Murphy is still lurking.

Injection Molding Mold Design Tutorial Mold design Guidance Upmold

Step-by-step calculations for product/mould shot size in injection moulding: Product/ Mould shot size = spruce volume + runner volume + product volume+ shrinkage. Step-by-step calculations for machine shot capacity/ shot size while designating injection moulding machines. Machine shot capacity (g)/ Machine shot size (mm), also known as the.

Injection molding process scheme Download Scientific Diagram

Injection Molding Shot Size Calculation is a widely used manufacturing process in which molten material, typically plastic, is injected into a mold cavity under high pressure. Once the material cools and solidifies, it takes the shape of the mold cavity, resulting in the production of a wide range of plastic parts and products.

TwoShot Injection MoldingPlastic Technologies Handbook

Shot Size Calc. Shot size calculator is very useful to select a machine. * ALL THE CALCULATIONS ARE FOR REFERENCE ONLY. POLYMER SCHOOL DOESN'T CLAIM ANY ACCURACY OF THE CALCULATION. USE WITH YOUR OWN JUDGEMENT. Begin typing your search above and press return to search. Press Esc to cancel.

Injection Molding Tolerances Four Ways to Optimize Them

Schematic of thermoplastic Injection molding machine 7. Process Operation Temperature: barrel zones, tool, die zone Pressures: injection max, hold Times: injection, hold, tool opening Shot size: screw travel. & shot size F=P X A = 420 tons 3.8 lbs = 2245 cm3 =75 oz Actual ; 2 cavity 800 ton 10. Clamp force and machine cost Boothroyd/Busch 11.

How Does Plastic Injection Molding Work?

The Crucial Role of Shot Size in Injection Molding: Balancing Precision and Efficiency. In the realm of injection moulding, the term "shot size" takes centre stage, referring to the volume of material injected into the mould during a single cycle. This vital parameter serves as the cornerstone of the moulding process, directly impacting the.

How to control injection molding part size?

To calculate the clamping force required for an injection molding machine, you can use the formula: Clamping Force (in tons) = Projected Area of Part (in square inches) × Tonnage Factor. The tonnage factor can vary but is often around 2 to 2.5 tons per square inch for typical materials like polypropylene.